Stand-alone CO System for Car Parks

CO System Working:

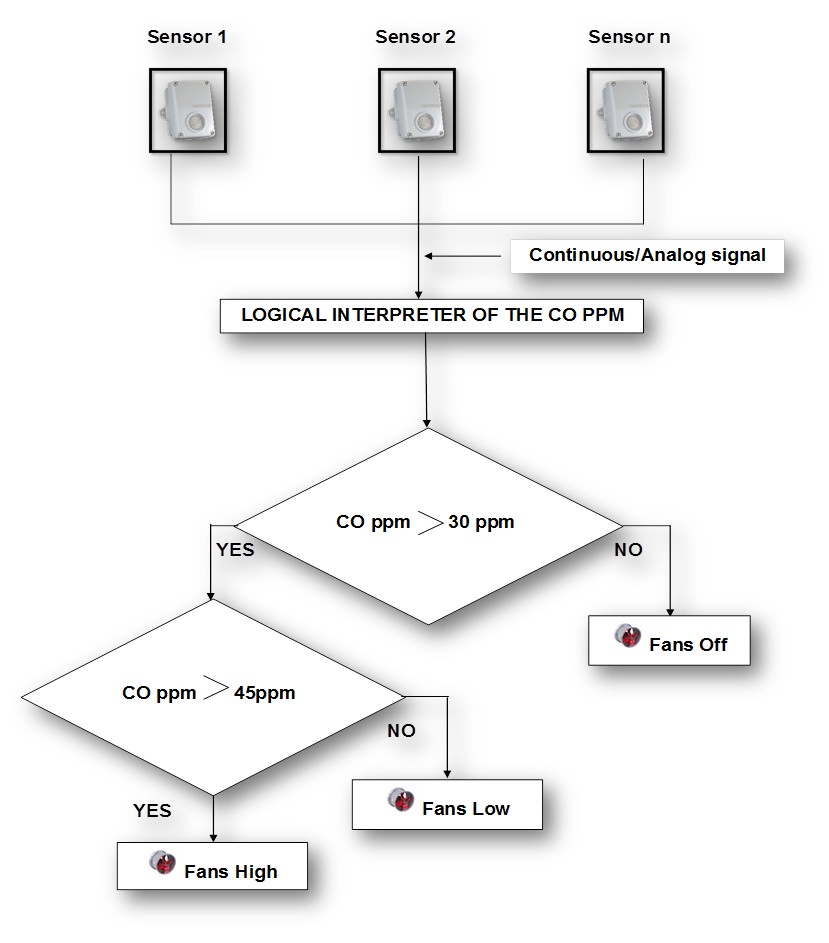

Our stand-alone CO system controls the operation of supply and extract ventilation fans depending on the concentration of CO in the basement car park area thus saving energy, while maintaining pre-specified CO levels. The CO sensor produces an analog signal depending upon the amount of CO present in the area surrounding the sensors. The signal from the sensors is processed by our controller to regulate the speed of the fans.

CO Sensor

Under normal operating condition when the CO concentration level is below a pre-set level (say 30 ppm - user settable) the exhaust fans could be idle. However, when the CO concentration is say between 30 ppm and 45 ppm (user settable) the exhaust fans could run at low speed and when the concentration exceeds say 45 ppm (user settable), the exhaust fans will run at high speed.

System Advantages:

1. User friendly and easily programmable PLC.

2. Flexible programming for virtual zoning in the car park.

3. Modular and easily expandable (8, 16 & 24 Sensors)

4. PLC displays the measured CO ppm of different channels along with channel number.

5. Stand alone or easily connectable to BMS System (RS 485) with add-on cards available as optional attachments.

6. A single PLC system can cover up to a maximum of 9,600 m2 of basement area. Multiple systems are possible due to modular nature of the electronics.

7. Equipped with provision to accept the signal from fire panel for fire mode.

8. CO Sensors are Greystone make with no calibration required for 3 years.

9. Maintenance of CO sensors requires just cleaning of the sensor with normal cotton cloth once in six month to remove the dust accumulated on it.

PLC Panel-Front View PLC Panel Rear View PLC & Fan Control

Shown below is a typical control strategy, implemented by our system: